More environmentally friendly lighting options, are becoming more popular as customers try to live sustainably. Consumers prefer the Chandeliers made of metal, glass, and crystal, which boosts lamp sales and propels the market's growth. Middle-class people are willing to try new things and spend money on items that align with their priorities despite their high pickiness. Even if a substantial fraction of this class is employed, it is helpful for businesses since it raises the possibility that they will buy goods supporting their pursuit of excellence. As a result, more people will purchase non-essential products like lamps as the proportion of people with more disposable income rises. In turn, this would aid the market's expansion of the chandeliers in the next years.

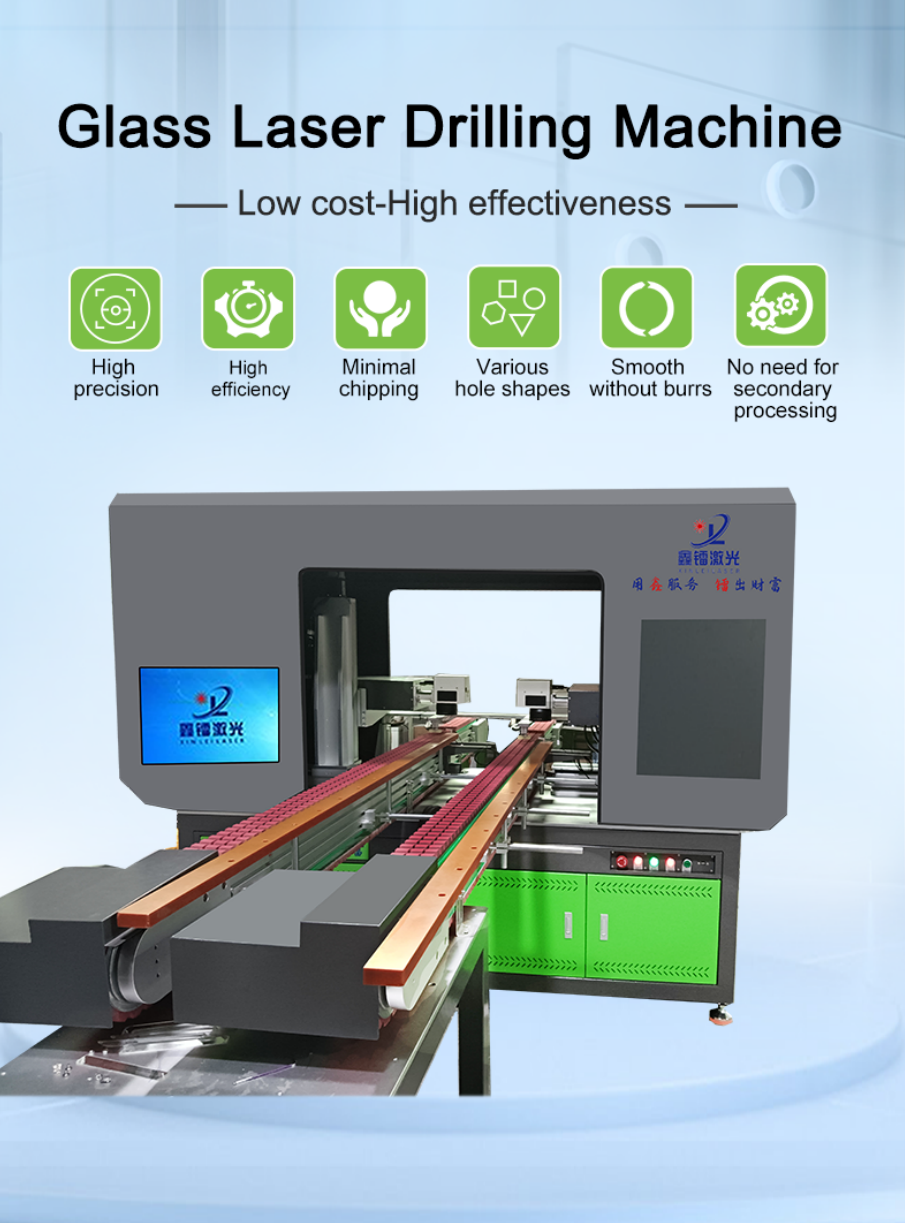

Chandeliers often exhibit intricate craftsmanship, and a significant limitation in the chandelier market is the high maintenance costs associated with these decorative lighting fixtures. Therefore, Xinlei Laser's crystal lamp decorative strip glass laser drilling machine came into being.

Xinlei Laser's crystal lighting strip glass laser drilling machine has many advantages, which makes it highly competitive in the crystal lighting industry.

First of all, compared with traditional mechanical drilling, the laser glass drilling machine has the characteristics of smooth edges and no burrs. The laser glass drilling machine uses non-contact processing, which does not produce mechanical pressure on the material, avoids damage to the material, and ensures the quality of the product, allowing lighting manufacturers to easily realize various complex and exquisite designs.

Secondly, compared with traditional mechanical piercing, laser glass drilling machines have the characteristics of high precision and high speed. Suitable for a variety of thicknesses and hole diameters, including micropores, small holes, large holes, and special-shaped holes. It can achieve fast and accurate drilling of glass, which greatly improves production efficiency and also makes the design of lighting fixtures more creative and personalized.

In addition, compared with traditional mechanical punching, laser glass drilling machines are characterized by high flexibility. The glass laser drilling machine also has the advantages of high degree of automation and easy operation, which reduces labor costs for production companies and solves a major limitation in the chandelier market.

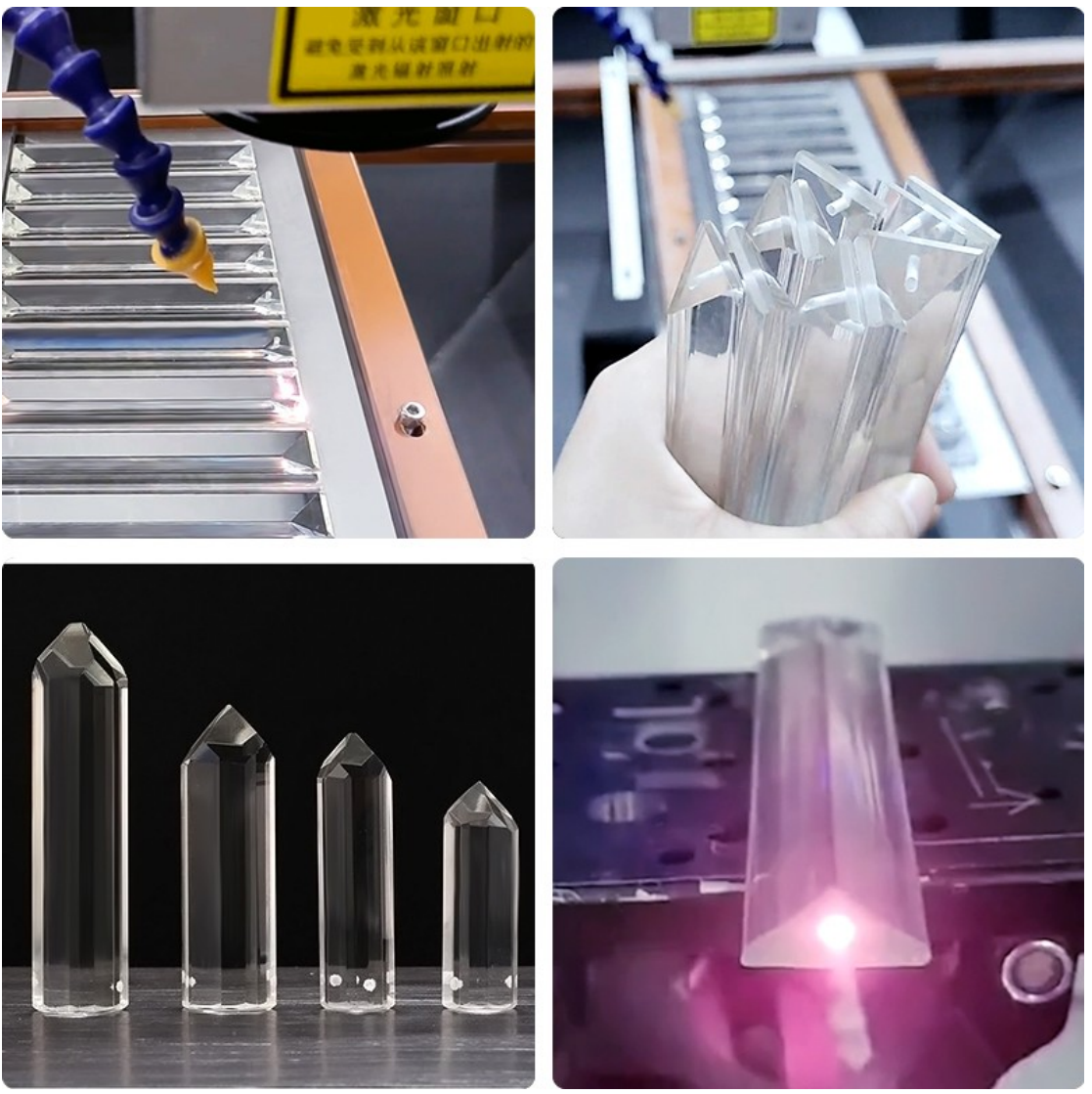

Display of our patented finished products of crystal lamp trim glass laser drilling machine:

Glass laser drilling machines can be widely used in the manufacture of various lamps, such as chandeliers, floor lamps, table lamps, wall lamps, etc. It is recommended to use laser drilling equipment for production. In addition, glass laser drilling equipment can also be used to process glass tubes, glass tea sets and other lighting materials, making the lighting more artistic and ornamental.

Recommended other glass laser equipment are:

The lighting manufacturing industry is showing a trend of diversification and personalization. Glass laser drilling machines have become an important tool in the modern lighting manufacturing industry due to their high precision, high efficiency, high flexibility and other advantages. In the future development, glass laser drilling equipment will be continuously optimized and upgraded, bringing more innovations and breakthroughs to more industries.

TAGS

DON'T MISS Xinlei Laser's News. SIGN UP FOR OUR EMAIL.