Choosing a laser marking machine is the same as when we buy things. The best is not necessarily the most expensive, and the most expensive is not necessarily the most suitable. Let me tell you some tips on buying a laser marking machine:

1. Light source for laser marking machine

First, confirm the customer's product material, because different materials absorb laser light to different degrees, and the degree of light absorption is determined by the wavelength of the laser. The laser wavelength is also named the laser source. Therefore, different laser sources must be selected for different materials.

Fiber laser marking machine:Wavelength 1064nm, main application areas: hardware, plastics, label paper, etc.;

Carbon dioxide laser marking machine (CO2 laser marking machine):Wavelength 10.6nm, main application fields: bamboo, fabric, ceramics, acrylic, leather, etc.;

Ultraviolet laser marking machine (UV laser marking machine):Wavelength 355nm, main application areas: silicone, UV plastic, paper, glass and other heat-sensitive materials;

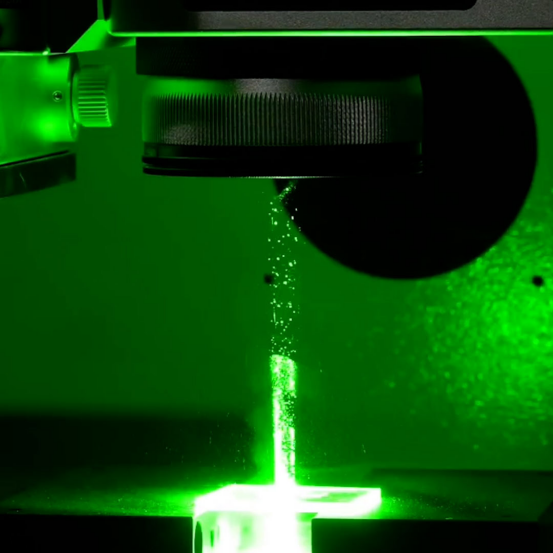

Green light laser marking machine:Wavelength 532nm, main application areas: film, fruit, eggs, cartons, tempered glass and other heat-sensitive materials (because green light is currently only used for glass interior engraving effects on the market, and other applications are basically replaced by UV machines).

What many customers want to know is, can a material only be marked with one laser source?

Of course not. Some materials are suitable for a variety of laser sources, but the degree of absorption of laser wavelengths is different, and the resulting effects are also different, depending on the customer's acceptance. For example, glass marking can use three laser sources: CO2, UV and Green light, with different effects:

CO2 laser marking machine: The marked glass is rough and prone to glass slag;

UV laser marking machine: cold light source, glass marking is very fine and uniform, and the effect is good;

Green laser marking machine: internal engraving on glass, internal plane engraving.

Therefore, it is not certain what effect each light source will have on the material. The specific effect required must be confirmed through proofing to confirm the final decision.

2. Power of marking machine

Laser power is sometimes the key to determining speed and effect. Different laser sources have the most stable power range:

The 20W/30W power of fiber laser marking machine is the most stable;

The 30W power of CO2 laser marking machine is the most stable;

The 3W/5W power of UV laser marking machine is the most stable.

The first thing to do is to determine the material of the product. For example, if the UV machine is used to engrave paper, film, or plastic, it can be 3W. If it is glass ceramics, it will need more than 5W.

The second focus is on efficiency and quality. For example, for marking hardware products, 20W optical fiber is generally used. However, if you pursue efficiency, speed and depth, you must at least choose 30W or 50W.

3. Main hardware configuration of laser marking machine

(1) Laser

That is, the laser source, the core of the laser marking equipment, is installed in the equipment casing. In the past, imported fiber lasers had good output modes and long service life. Nowadays, the technology of China's laser industry is becoming increasingly mature, and the lifespan and performance of lasers are comparable to imported lasers. However, for users with very high precision requirements, it is recommended to explain and make requirements to us in advance.

(2) Laser scanning galvanometer

The optical scanning galvanometer is also the core component of the laser marking machine. It is mainly used to quickly and accurately position the beam. The performance of the galvanometer determines the accuracy of the marking machine.

(3) Focus system

The focusing system focuses the parallel laser beam on a point, mainly using f-theta lens (also called field lens). Different field lenses have different focal lengths, and the marking effects and ranges are also different. The standard field lens of our company's fiber laser marking machine is f=254mm, and the effective marking range is 175*175mm. Some companies' standard field lenses are smaller. Customers need to confirm with us when purchasing. They can also choose the appropriate field lens model based on their own products and required marking range:

f=100mm, the effective marking range is 75*75mm

f=160mm, the effective marking range is 110*110mm

f=210mm, the effective marking range is 150*150mm

f=254mm, the effective marking range is 175*175mm

f=330mm, the effective marking range is 220*220mm

f=420mm, the effective marking range is 300*300mm

(4) Laser power supply

The input voltage of the laser power supply is generally AC220V. If customers in some countries and regions require AC110V, please inform us in advance.

(5) Computer control system

The combination of laser operating system and computer numerical control technology forms an efficient automated processing equipment that can mark various texts, patterns, symbols, one-dimensional codes, two-dimensional codes, etc. It is easy to use software to design marking patterns and change marking content to meet the modern needs of high production efficiency and fast pace.

There are many kinds of software used on laser marking machines, some are conventional, some are developed by ourselves, or conventional software is re-developed. It mainly depends on what control card the equipment manufacturer uses to decide what software to use. Recommended several types:

The first type: BEIJING JCZ. The marking software is EZCAD2. This software is used the most and has many designed patterns. The main problem is that the secondary development is difficult.

The second type: KINGYU software, this software is more conventional and can meet general needs. Secondary development is generally difficult. The user group is mainly for foreign markets, with more users in India and Thailand.

The third type: LS8001 software and marking card. There are not many users of this software, but its advantage is that it is not difficult to develop secondary software and can easily complete and add unused functions.

At present, the standard models used by our company are genuine cards, JCZ and LightBurn software; we also have self-developed models that have obtained the corresponding computer software copyright registration certificate and utility model patent certificate.

It supports TrueType fonts, single-line fonts (JSF), dot matrix fonts (DMF), ordinary computer fonts, as well as bitmaps and vectors, and you can also draw your own patterns.

It is compatible with output files from CorelDRAW, AutoCAD, Photoshop, AI and other software, and also supports PLT, DXF, JPG, BMP and other files. The marking software is easy to operate and powerful.

4. Place of origin

The three most well-known producing areas of laser marking machines in China are Shenzhen, Guangdong, Liaocheng, Shandong, and Zhejiang.

In Liaocheng, Shandong, there are many laser marking machines that are recycled, refurbished and sold second-hand. The price of fiber optic machines is as low as more than 10,000 or even 8,000 yuan.

Zhejiang continues to follow the e-commerce model, using low-cost accessories, making small profits but quick turnover, and the prices are relatively low.

Shenzhen, Guangdong, is also known as the "City of Design". Many high and new technologies are well developed here. Shenzhen's laser manufacturers also have relatively high requirements for the quality and production of equipment accessories. Laser technology is widely used in automation. The price of equipment is also higher than that in Shandong and Zhejiang.

5. Price

The price of fiber laser marking machine (20W-120W) is RMB 20,000-150,000;

The price of CO2 laser marking machine (10W-200W) is RMB 350,000-200,000;

The price of UV laser marking machine (3W-10W) is RMB 40,000-260,000;

Of course, these prices will change according to the configuration selected by the customer. Xinlei Laser provides non-standard automation solutions, and the price varies according to the customer's needs and configuration.

6. The life and stability

Laser will gradually be worn out during long-term use. Many people mistakenly believe that the greater the laser power, the longer it is consumed, and the longer the service life of the laser. In fact, the greater the laser power, the more heat is generated in the working environment. If the heat cannot be dissipated in time, the long-term high temperature of the equipment will shorten the life and easily burn out.

Therefore, equipment such as optical fiber 50W and ultraviolet equipment above 3W need to be equipped with a large cooling system for water cooling. Therefore, the higher the wattage, it does not guarantee a longer life. If the cooling system is not done well, it will be more likely to burn out and increase the cooling cost.

7. Product appearance and machine model

At this stage, laser marking machines have a mixed appearance and various styles. There are small portable laser marking machines, desktop laser marking machines with cabinet operating tables and computers, and flying laser marking machines designed to cooperate with automated assembly lines. .

8. After-sales service

The operation of the laser marking machine requires engineer guidance and training, especially the application skills, parameters and daily maintenance of the marking software.

The warranty period of electronic products is one year, and some manufacturers will promote the warranty period of three or five years to attract customers. In fact, the accessories of laser marking machines are well selected. Because the equipment has no consumables or consumable parts, the equipment has a high maintenance-free rate. Today's laser equipment has a life span of 60,000 to 100,000 hours.

★ Xinlei Laser has after-sales engineers who are responsible for connecting with customers, so that you can have worry-free after-sales service.

★ Xinlei Laser, as a manufacturer specializing in the production of laser equipment, quality, integrity, and service are our commitments that we have always adhered to.

9. About customization and others

If the customer has requirements for accuracy, marking effect, speed, cooperation with automation, customized fixtures, etc. when using laser equipment, the customer needs to propose it to the manufacturer in advance during the process of sample testing and plan development.

★ It is Xinlei Laser's responsibility to recommend to you the marking machine that best meets the customer's requirements.

Various types of laser marking machines produced by Xinlei Laser: integrated design, small size, low power consumption, long life, high efficiency, maintenance-free, high-quality laser beam, fine spot, and no consumables required.

DON'T MISS Xinlei Laser's News. SIGN UP FOR OUR EMAIL.